16. August '24

by Natalie Schalk

Small gimmicks are often the entry point into the world of 3D printing – just like Felix Felgenträger. The Sonneberg native is studying “Additive Manufacturing and Lightweight Design” at the Faculty of Mechanical and Automotive Engineering at Coburg University of Applied Sciences. This course, which is unique in Germany, is taught in Coburg and Lichtenfels and trains the experts needed for the future of industrial manufacturing. Felgenträger explains why 3D printing and lightweight construction are so revolutionary.

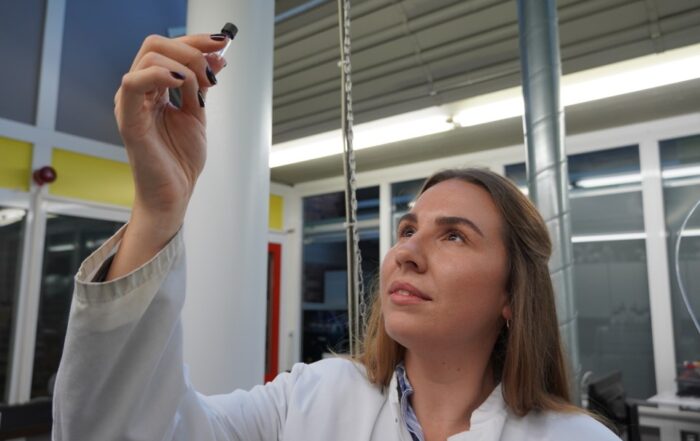

If a technology-loving twenty-something like Felix Felgenträger needs some curtain hooks today, he doesn’t think about where to buy them.He thinks about how to print them. The Thuringian has had a 3D printer at home in Sonneberg for some time and he believes that fused layer modeling (FLM) is the ideal solution for something as mundane as curtain hooks: filament, i.e. thermoplastic, is fused layer by layer to form a solid component. Felgenträger explains that in addition to curtain hooks, he has also “printed” fantasy figures from worlds such as Warhammer or Star Wars. For this, however, he used stereolithography (SLA), a method in which a liquid synthetic resin is hardened layer by layer with the help of light.

3D printing comprises various processes. Experts refer to this as additive manufacturing and see it as one of the most important future technologies for developing more sustainable products and processes. This is why Felix Felgenträger opted for the Additive Manufacturing and Lightweight Design (AL) Master’s degree course at Coburg University of Applied Sciences – even though he didn’t want to do a Master’s degree in the first place. “But then I just thought AL was cool because I had already tried out a few gimmicks with 3D printing in my private life,” he explains. Small things can be realized relatively easily.

The Sonneberg native has already completed a Bachelor’s degree in Technical Physics at Coburg University of Applied Sciences, just 20 minutes from his home town. He developed a pulse measuring device for his bachelor’s thesis. Here, too, the corresponding holder came from the 3D printer. But he only really realized what the technology – especially in connection with lightweight construction – is really capable of during his Master’s degree. Additive Manufacturing and Lightweight Design is taught in Coburg and Lichtenfels, as Coburg University of Applied Sciences cooperates with the Lichtenfels Research and Application Center for Digital Future Technologies (FADZ). Felix Felgenträger now travels by train more often.

What the industry needs

Making components lighter, cheaper and more efficient. Or simply more individual. This makes 3D printing and lightweight construction attractive for many industries. The AL degree course focuses on applications in the automotive industry, aerospace technology, construction industry or medical technology and on structures made from various plastics or metals. In three semesters, the fields of mechanical engineering, materials technology, technical product design and automation technology are combined. “Additive Manufacturing and Lightweight Design” is the only degree course in Germany with this focus. “The course is open to Bachelor’s graduates from various engineering disciplines,” explains course director Prof. Dr. Markus Stark. “Using less material saves resources.” It saves material in production and if less mass has to be moved, this saves energy during transportation and later also during use. Good for the environment – and very economical at the same time. “There is great demand from companies in this area. Our graduates are in demand in the industry,” says Stark.

Numerous industrial companies from the region are represented in the FADZ business association and there are many companies in Upper Franconia, Thuringia and Saxony that are involved in these technologies. There are always interesting collaborations and practical projects for AL students and contacts with companies are established during their studies. Stark sees the practical orientation and close links with the regional economy as major advantages of the course.

Steel, aluminum or cobalt: anything is conceivable in the simulation

Felix Felgenträger explains how this works in everyday student life. A practical project involved optimizing a part for a leg prosthesis. The students scanned it, transferred it to a file and simulated what would change with different structures or materials. “I tried it with cobalt: It was just relatively heavy,” the 26-year-old grins, “and expensive. But it would have been perfect for high temperatures of around 600 degrees!” Studying is fun. Simulations such as the finite element method and topology optimization allow free experimentation with the technological possibilities. “For example, we simulate where there are high stresses, how forces act and where I can omit material.” A component in the car interior that is exposed to little stress can be designed as a lattice structure. “Where stronger forces act, I need a truss structure, a support structure.” Such optimized, often complex designs can also be produced in real life using 3D printing. “And if I need cooling channels or something else, I can integrate it right away. That’s great, of course,” says the student enthusiastically. And as far as the part for the leg prosthesis is concerned: an optimized structure and an ideal material were also found for this “In the end, we created a lightweight lattice product. Instead of the previous 600 grams, it weighs around 300 grams.”

Further information

Registration for the winter semester is currently possible here until September 30; information on “Additive Manufacturing and Lightweight Design” is available at www.hs-coburg.de/al. An information event on the course will take place online via Zoom on Wednesday, September 18, between 6 and 7 pm. Find out more in the university’s calendar of events at www.hs-coburg.de/veranstaltungen.html