17. May '24

from Natalie Schalk

You can’t just quickly open a window in a highway tunnel or shopping center – but modern technology ensures that there is no thick air.

Large industrial ventilation systems work so well that they are barely noticeable in everyday life, but they do have one disadvantage: energy consumption.

The European Union has announced that it will tighten the Ecodesign Directive for industrial fans next year.

In his doctoral thesis at Coburg University of Applied Sciences and FAU Erlangen-Nuremberg, Manuel Fritsche has developed a solution to this problem. There is a need for action in the area of fans.

The reason for this is an EU regulation: No. 327/2011 as part of the ErP Directive 2009/125/EC stipulates ever stricter energy efficiency requirements for these machines.

“The minimum efficiency level is being systematically increased by the legislator over time,” says Manuel Fritsche.

“This represents a serious technical challenge for fan manufacturers.”

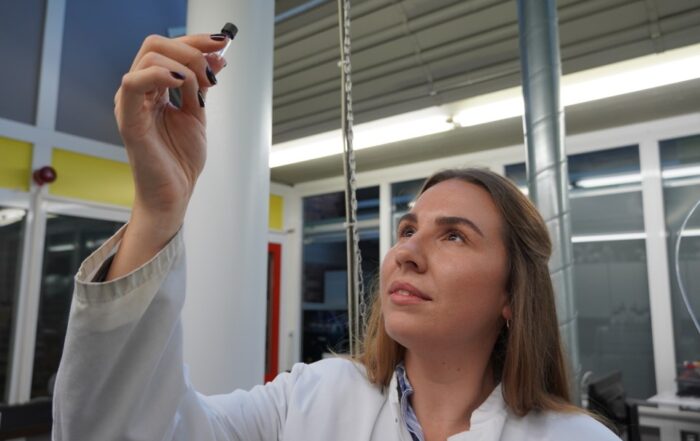

Fritsche is sitting at a computer in the laboratory for fluid mechanics at Coburg University of Applied Sciences; the two large screens in front of him show merging pink, yellow and green.

“Numerical flow simulations,” he explains.

To visualize them, he calculates how various factors influence the air flow at the fan.

“Flows are complex processes: there’s turbulence, three-dimensionality, instationarity.”

How air flows depends on how they interact.

If, for example, turbulence occurs on the fan blade, the energy is not converted well; the efficiency is poor.

Ideally, the air simply flows along the fan blade.

“Engineers have been thinking about the optimum flow direction for a long time,” reports Fritsche.

“They then created several prototypes and tested what worked best.”

For around 20 years now, these tests have increasingly shifted to computer simulations and instead of building a few prototypes as in the past, the 34-year-old carried out thousands of simulations for his doctoral thesis. Where previously known methods fail The well-known design methods are based on a cylindrical hub shape and aerodynamically profiled blades, for which empirical profile data is required.

In industrial practice, however, low-pressure axial fans are usually manufactured with three-dimensionally curved blades made of sheet metal of the same thickness for cost and production reasons.

Fritsche has therefore developed a “simulation-driven design and optimization strategy for the application of an axial fan with guide vane”.

He was awarded “Magna Cum Laude” for the above-average performance of this doctoral thesis.

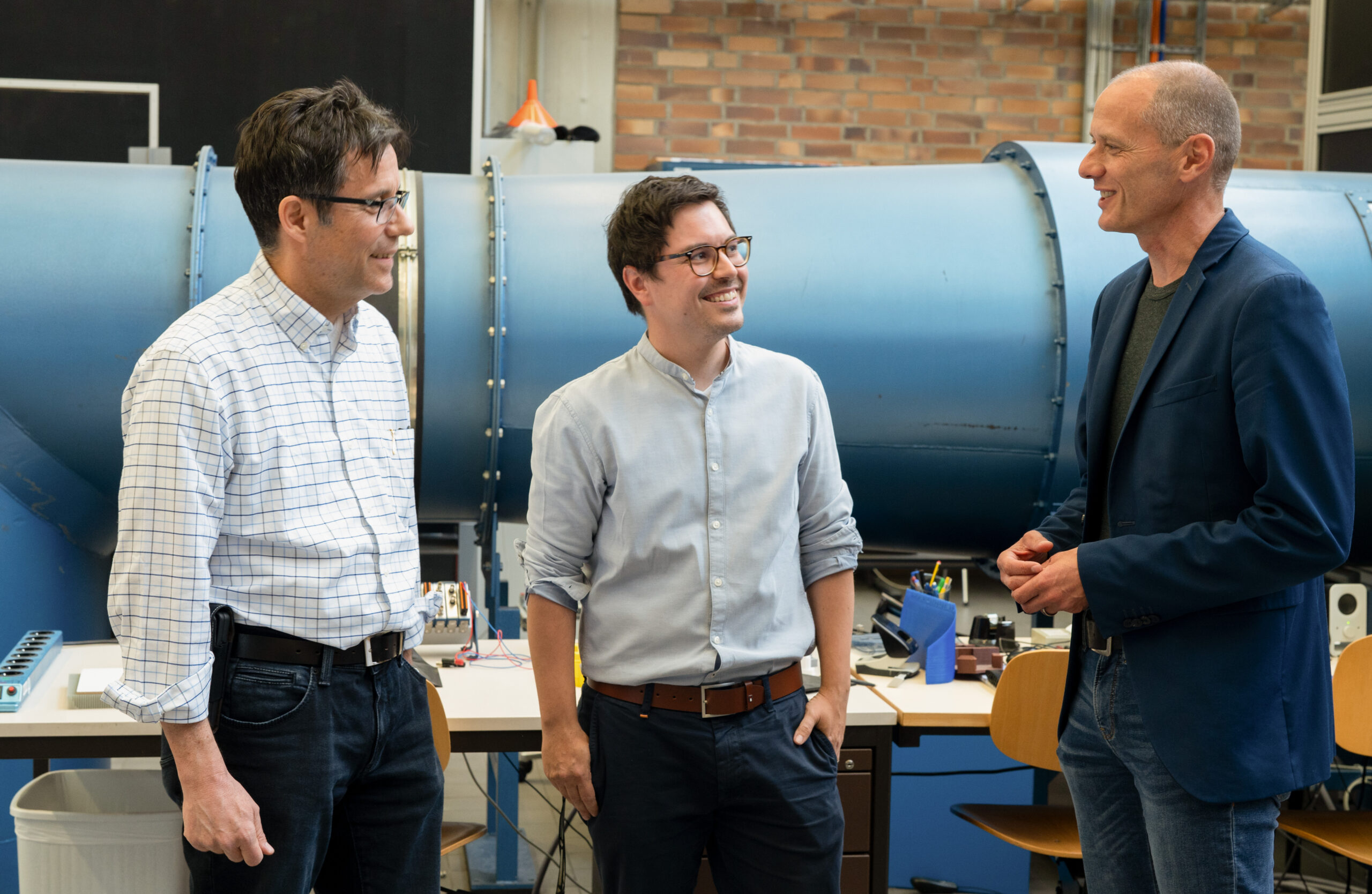

The cooperative doctorate at the Faculty of Mechanical and Automotive Engineering at Coburg University of Applied Sciences was supervised by Prof. Dr. Philipp Epple, Head of the Laboratory for Fluid Mechanics, and Prof. Dr. Antonio Delgado from the Chair of Fluid Mechanics at Friedrich-Alexander-Universität Erlangen-Nürnberg. From his first semester to his doctorate at the university Epple is delighted that his research assistant has completed his doctorate.

Fritsche has been associated with the university for a long time.

He lives in Ebensfeld in the district of Lichtenfels, has already completed his diploma and master’s degree at the Faculty of Mechanical and Automotive Engineering at Coburg University of Applied Sciences and will remain at the faculty as a postdoc after completing his doctorate.

His Coburg doctoral supervisor Epple thanks the Dean, Prof. Dr. Alexander Rost, for supporting this doctoral process.

“My special thanks also go to the university management,” says Epple. “In particular, our President Prof. Dr. Stefan Gast and our Vice President for Research, Prof. Dr. Martin Synold, have created the necessary framework conditions and are constantly supporting research and doctoral projects.” Science and industry: a successful transfer project President Gast himself comes from the Faculty of Mechanical and Automotive Engineering, has experienced Fritsche’s work up close for some time and is delighted that the research findings from this doctoral thesis are being transferred into industrial practice.

The dissertation is part of a cooperation project between Coburg University of Applied Sciences and a fan manufacturer, which is funded by the Central Innovation Program for SMEs (ZIM) of the Federal Ministry of Economics.

Fritsche’s new design and optimization method was validated with the help of prototypes from the industrial partner.

“The Institute for Prototype and Model Technology at Coburg University of Applied Sciences also created fans for me as hand samples using the 3D printing process,” adds the doctoral student.

Based on his research, axial fans can now be designed with significant increases in efficiency and optimized operating behaviour.

This will help to meet the stricter EU directive in the future.

Wherever large ventilation systems are used, such as in parking garages or shopping centers, the process developed can improve the energy efficiency of fans – and that gets to the heart of the sometimes cumbersome EU regulations: it is a contribution to climate protection.