15. August '24

By Natalie Schalk

Shadow mask lithography can be used to create tiny patterns on surfaces. The Institute for Sensor and Actuator Technology (ISAT) at Coburg University of Applied Sciences has now succeeded for the first time in producing plasmonic nanostructures using this technique – and this has great potential for the development of highly sensitive sensors.

Nano comes from the Greek, meaning dwarf, and nanotechnology is the science and technology of tiny nanoparticles. There are so-called plasmonic nanoparticles, which have special optical properties: Plasmonic structures interact with light in a defined way and can be customized for sensor applications as well as optoelectronic interactions. They can focus light in an incredibly small space, which is crucial for the development of highly sensitive sensors. These sensors have the potential to permanently improve sensor technology in areas such as medicine, environmental monitoring, occupational health and safety. Some highly sensitive sensors for gas diagnostics are also based on these interactions – an exciting field for the Institute for Sensor and Actuator Technology (ISAT) at Coburg University of Applied Sciences.

The team is delighted that research into plasmonic structures has taken a significant step forward: for the first time, it has been possible to produce plasmonic nanostructures using shadow mask lithography.

From the Chinese partner university to the Coburg ISAT

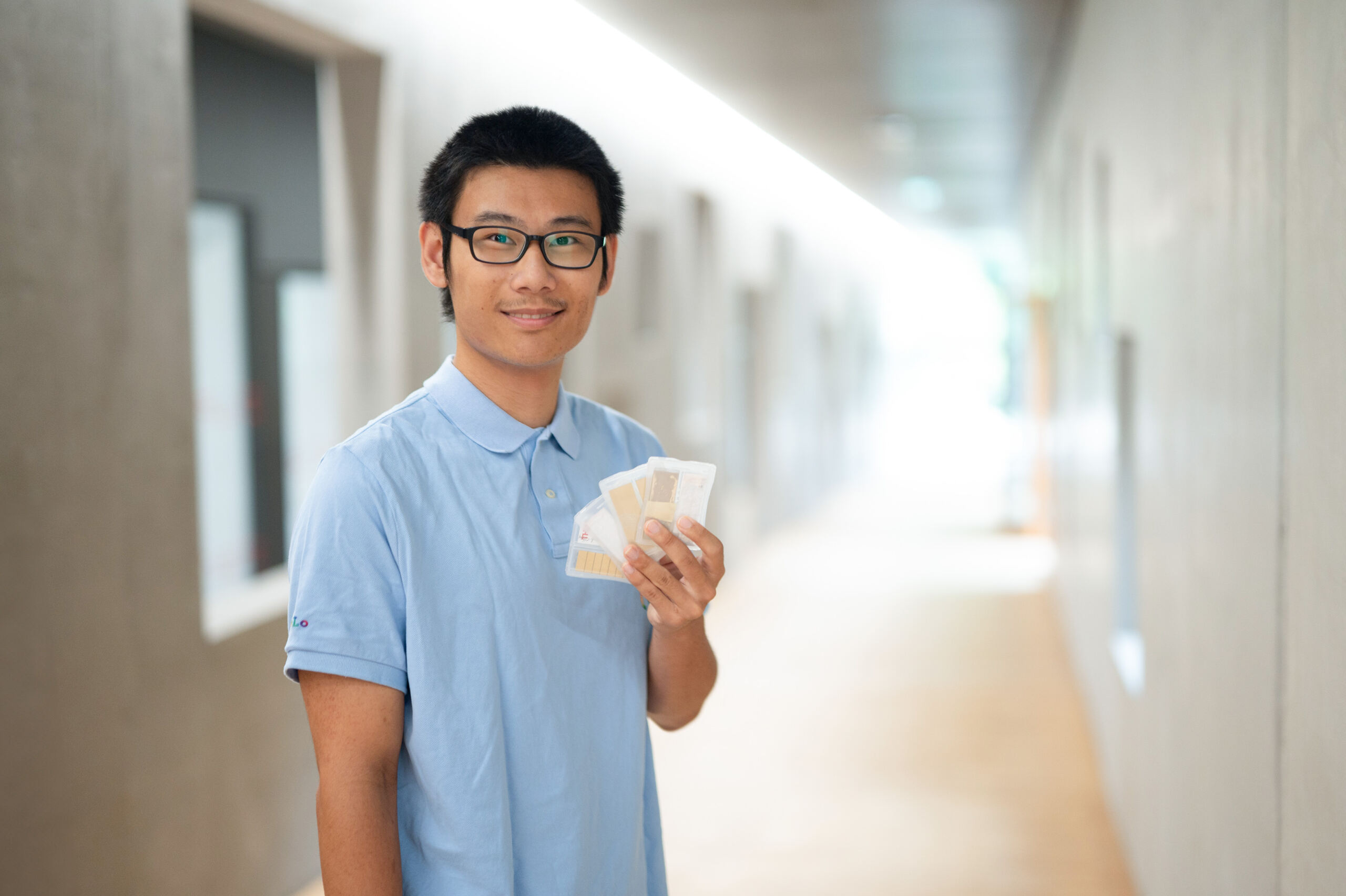

This success is the result of Yuzhong Shi’s practical semester. The student from China has completed a year at Coburg University of Applied Sciences on the Bachelor’s degree course in Future Technologies and has been at ISAT for his practical semester in recent months.

“That really broadened my horizons,” he says. Many things here are very different from China: there is not rice for every meal, the culture and entertainment in Franconia are different – and there are many opportunities for practical work at Coburg University of Applied Sciences.

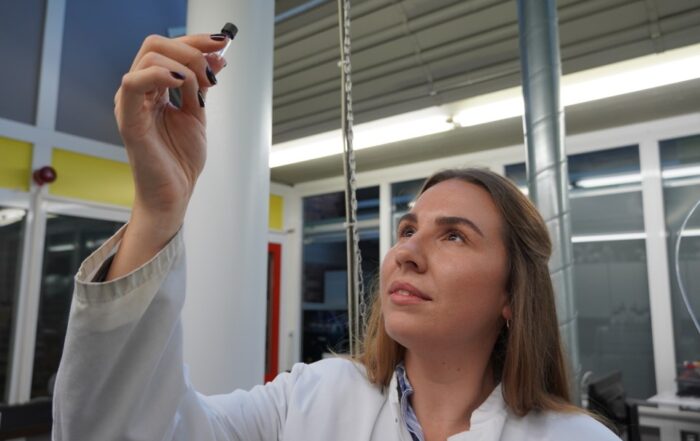

Shi smiles: “Opportunities to go into the lab and simply do nano research.” In his practical semester, he produced plasmonic nanostructures using shadow mask lithography with polystyrene microspheres as a mask for sputter deposition. The work was carried out at ISAT under the supervision of Klaus Lutter, Sandra Ebert and Prof. Dr. Thorsten Uphues . “At the university, we are happy to support young, motivated researchers to work on such complicated topics,” says Uphues.

A star-shaped pattern of triangular silver structures

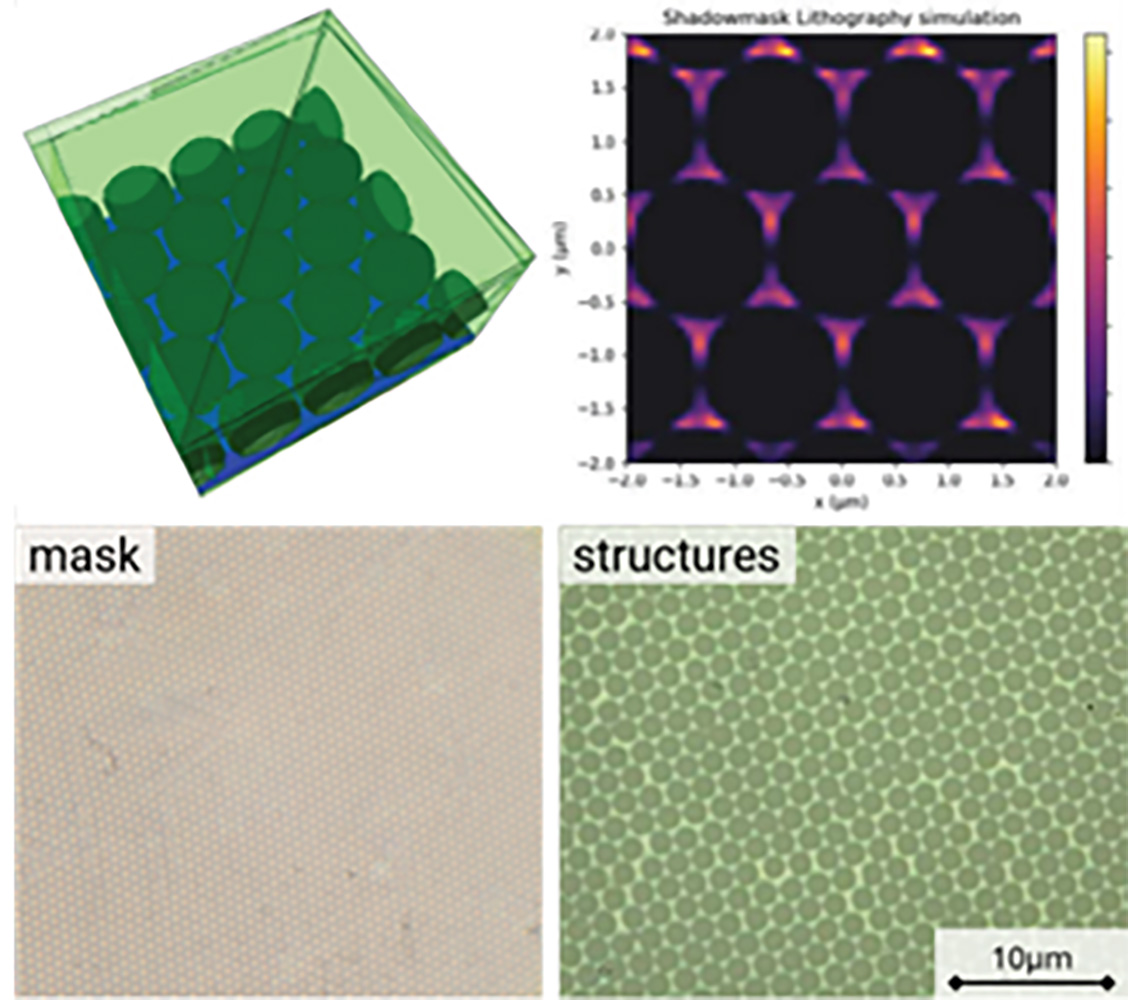

Shadow mask lithography is a technique that can be used to create tiny patterns on a surface. A mask with specific openings is placed between the substrate and a sputter source. The sputtering material is applied through the openings, creating the desired pattern on the surface.

The mask is then removed and the structures remain on the surface. This method offers a simple yet precise way of producing nanostructures. In this particular work, a star-shaped pattern of triangular silver structures was created.