Additive Manufacturing and Lightweight Design

At a glance

Academic degree

Master of Engineering (M.Eng.)

Form of study

Consecutive Master

Standard period of study

3 semesters (incl. Master's thesis), 90 ECTS, extension to 5 semesters possible

Study locations

Language of instruction

German

Start of studies

Winter semester (October 01)

Summer semester (March 15)

Admission requirement

- University degree or other equivalent qualification in mechanical engineering, automotive engineering, mechatronics, information technology/computer science, electrical engineering/electronics, physics, materials science, industrial engineering, mathematics or a related course of study

- Generally 210 ECTS including a practical semester; for degrees with 180 ECTS, missing ECTS in theory or practice can be made up before the start of studies or within one year after the start of studies. Recognition is possible.

- Further information can be found below and in the study and examination regulations

- For international applicants: all information about the application including an overview of the required language certificates here

Costs

Semester fee (incl. semester ticket)

Studying with a practice partner

On request as a degree course with in-depth practical experience (PraxisPlus)

Accreditation

accredited by the Accreditation Council

Info presentation

Registration

from May 02 – June 15 (for winter semester)

from November 15 – March 14 (for summer semester)

Profile of the Master's program

New technologies are helping us to develop more sustainable products and processes. 3D printing is one of these technologies of the future. In combination with lightweight construction and new materials, it can contribute to a more environmentally friendly approach. The economy has a great need for qualified employees with skills in the field of additive manufacturing.

![]() In the Master's in Additive Manufacturing and Lightweight Design, students learn about the current trends and developments in these technologies and acquire the skills to apply them in the development and production process – e.g. artificial intelligence, automation, sustainability. e.g. artificial intelligence, automation, sustainability.

In the Master's in Additive Manufacturing and Lightweight Design, students learn about the current trends and developments in these technologies and acquire the skills to apply them in the development and production process – e.g. artificial intelligence, automation, sustainability. e.g. artificial intelligence, automation, sustainability.

Prof. Dr. Markus Stark

We will inform you!

Next info dates:

-

- Tuesday, 18.11.2025, 6-7 p.m. | Microsoft Teams Link

- Wednesday, 10.12.2025, 6-7 p.m. | Microsoft Teams Link

- Tuesday, 13.01.2026, 6-7 p.m. | Microsoft Teams Link

- Thursday, 05.02.2026, 6-7 p.m. | Microsoft Teams Link

- Tuesday, 24.02.2026, 6-7 p.m. | Microsoft Teams Link

What we value

Practical and project-oriented

The focus is on practical and project-oriented studies. Students learn skills and apply them immediately in specific projects. They solve the tasks together in teams with other students. In addition to the lecturers, they also receive specialist input from companies, e.g. in the form of keynote speeches.

Coburg University of Applied Sciences is cooperating with the Research and Application Center for Digital Future Technologies (FADZ) in Lichtenfels on the Additive Manufacturing and Lightweight Design course. Students can therefore benefit from both a strong research focus (university) and a high level of application orientation (company).

Studying in Coburg and Lichentenfels

Half of the students on the Additive Manufacturing and Lightweight Design Master's degree course complete their studies at Coburg University of Applied Sciences. Another study location is the Research and Application Center for Digital Future Technologies (FADZ) in Lichtenfels. The premises are currently located in Laurenzistraße – right in the city center. A move to the renovated premises of the former Kirschbaummühle is planned at a later date. One module per semester takes place at one of the two locations. Daily commuting between the locations is therefore not necessary.

Lichtenfels is not only a basket-making town, but also the cradle of metal 3D printing. University graduate Frank Herzog invented this technology and brought it to market maturity. The Coburg University of Applied Sciences is closely linked to the FADZ Förderverein and therefore also benefits from a broad network of companies in the Coburg-Kronach-Lichtenfels innovation triangle. The region around Lichtenfels is characterized by numerous cultural highlights. The town lies at the foot of the Staffelberg and is framed by the Banz and Vierzehnheiligen monasteries. Because of its scenic beauty, this area is also known as the "Garden of God". Students here benefit from a high quality of life and affordable living space. Coburg can be reached quickly and easily by train and the journey is free thanks to the semester ticket. There are also very good connections to Bamberg.

Course content and schedule

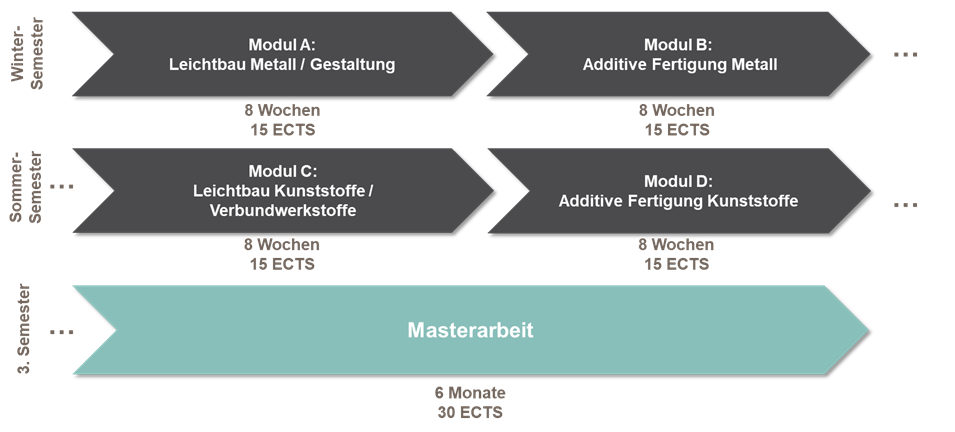

The course consists of four modules in two semesters. The Master's thesis is planned for the third semester. The projects are worked on by the students in teams. Lecturers and experts from industry provide specialist input and are available as coaches during the project phase. There are two modules per semester – one on additive manufacturing and one on lightweight construction. In the summer semester, the focus is on the material metal, in the winter semester on the material plastic.

A. Modules in the winter semester

Module A: Lightweight construction - metal/design

- Project management

- Fundamentals of lightweight construction (e.g. topology optimization) and fatigue strength

- Lightweight materials Metal

- Manufacturing techniques

- Quality management

- Sustainability

- Supervised project work

Module B: Additive manufacturing - metal

- Additive manufacturing processes with metals

- Designing products for additive manufacturing with metals

- Materials and analysis

- Post-processing

- Quality assurance, optics, laser technology

- Business management basics, calculation, sustainability

- Supervised project work, parameter study

B. Modules in the summer semester:

Module C: Lightweight construction - plastics/composites

- Materials for fiber composite construction (matrix material, fibers, processing forms)

- Processing techniques for composite materials, sandwich structures, mold construction

- Innovative product development

- Material selection

- Calculation of structures

- Automation, Prompt Engineering

- Supervised project work

Module D: Additive manufacturing - plastics

- Additive manufacturing processes with metals

- Designing products for additive manufacturing with metals

- Materials and analysis

- Post-processing

- Quality assurance, optics, laser technology

- Business management basics, calculation, sustainability

- Supervised project work, parameter study

C. Contents of the 3rd semester:

Writing the Master's thesis

The Master's thesis can be written in cooperation with a company, for example. Part-time study over five years is generally possible. The study and examination schedule provides an overview of the structure of the degree program. The The module handbook provides information on the content of the individual modules. The study and examination regulations form the legal basis of the degree program. Questions about the content of the course will be answered by the course director Prof. Dr. Markus Stark.

Voices of our cooperation partners

Frank Carsten Herzog, FADZ

"The additive manufacturing method is on the threshold of industrialization and therefore also the mass production of additively designed components. Taking into account the current debate on climate change and the ever-increasing demand for energy, the topic of lightweight construction has a key role to play. The new Master's degree course in Additive Manufacturing and Lightweight Design could not be better placed in terms of time and location. Lichtenfels is now regarded as a global hotspot for additive manufacturing as a place of work for future students – with investments by local companies amounting to 250 million euros in the last four years alone. " Read more

Siegfried Russwurm, Federation of German Industries

"There is no doubt that 3D printing has moved beyond the 'exotic' phase. Thanks to additive manufacturing, components can be designed that could not be produced conventionally. This is one of the biggest productivity levers. This is why the Additive Manufacturing & Lightweight Design course at Coburg University of Applied Sciences is so right and important. I am sure that graduates of the new course will not have to worry about jobs." Read more

Dr. Markus Weber, Hans Weber Maschinenfabrik

"3D printing can be seen as the third industrial revolution. Individual mass production, lightweight construction or decentralized" green "production are just three of the many convincing arguments for the versatile use of additive manufacturing processes. The Master's degree program in Additive Manufacturing and Lightweight Design at Coburg University of Applied Sciences comes at exactly the right time and in exactly the right place for us. All doors are open to graduates with this qualification." Read more

Jan Beier, Bullfrog Marketing & Design

"Lightweight construction solutions not only enable us to reduce the weight of our upholstered furniture, but also save valuable resources and open up new possibilities for furniture design – all of this is now within our grasp in the truest sense of the word thanks to the new" Additive Manufacturing and Lightweight Design "course. We expect the course to provide valuable impetus for the further development of our products in order to ensure our competitiveness in the future. We are looking forward to the student projects and the collaboration with Coburg University of Applied Sciences!" Read more

Job & Career

Sustainable products and processes will become increasingly important. The combination of additive manufacturing and lightweight construction opens up completely new possibilities for this. These technologies are already being used in many areas of industry, e.g. in mechanical engineering and toolmaking, aerospace and medical technology. The combination of additive manufacturing and lightweight construction results in new product solutions that save resources and are becoming increasingly important in terms of sustainability. Graduates of the Additive Manufacturing and Lightweight Design course therefore have numerous options open to them. We are looking for specialists and managers along the entire process chain – from technology development to application in design and production, programming or process optimization. Through the practice-oriented course, students establish contacts with companies that will help them to enter professional life. At the same time, the Master's course offers students the opportunity to gain further qualifications while working and thus bring new perspectives to their own company.

Do your doctorate now!

Graduates with a good Master's degree can continue to work academically after completing their Master's degree. For example, it may be possible to write a doctoral thesis at Coburg University of Applied Sciences and complete a doctorate in cooperation with a university.

Insights

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationApplication and admission

Admission requirements

- Completed university degree in mechanical engineering, automotive engineering, mechatronics, information technology/computer science, electrical engineering/electronics, physics, materials science, industrial engineering, mathematics or a related course of study

- At least 210 ECTS (usually 7 semesters) including a practical semester (min. 18 ECTS). Missing competencies in theory and practice can be made up within one year of starting the Master's program

- Language level B2 of the German language